It was probably around the start of October that I was talking to Kamala saying that we needed to make some art for our living room. For some reason she responded with something along the lines of:

"I think it would be cool to have a wooden model ship on the wall instead a painting."

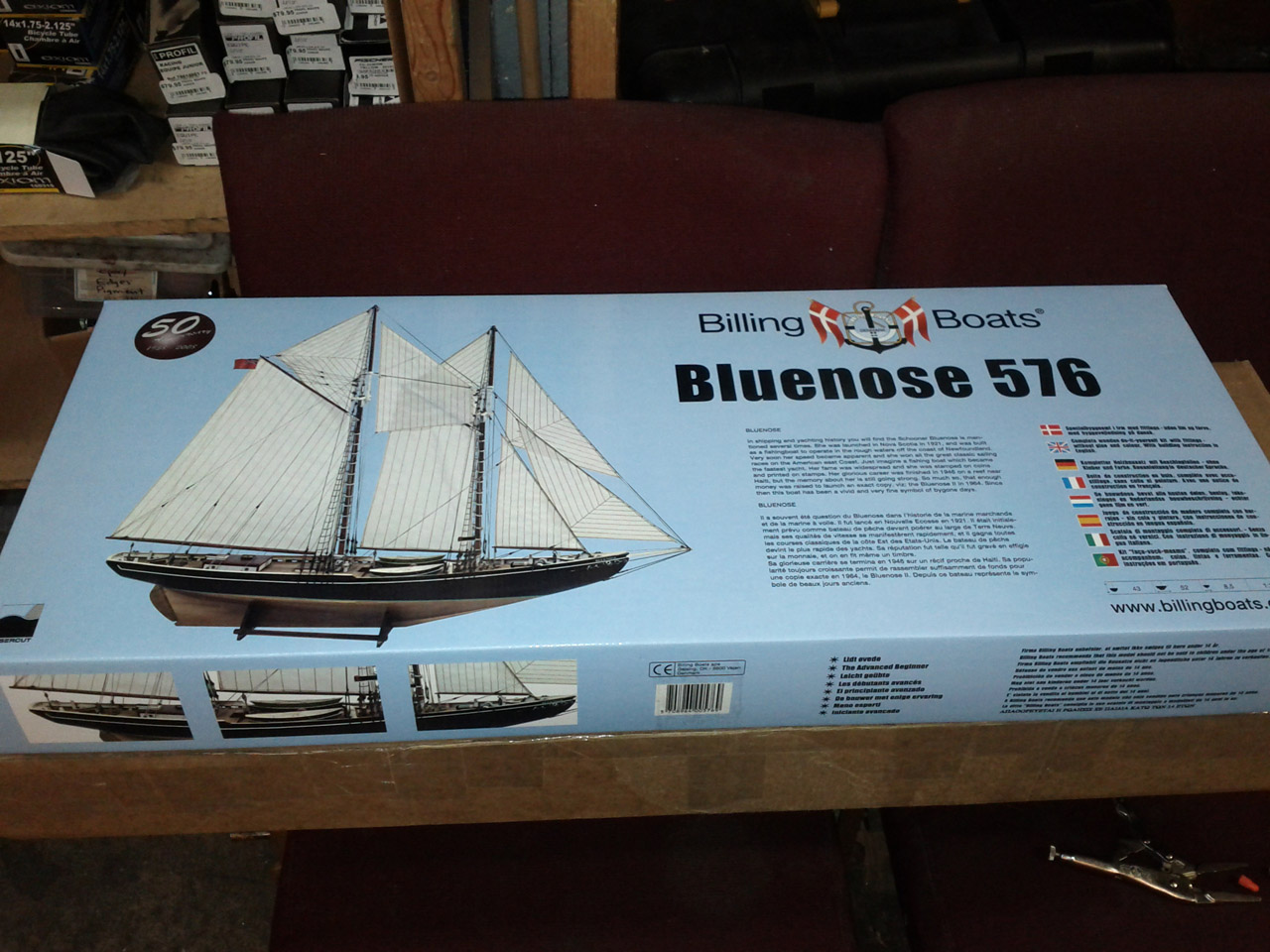

For some reason I agreed to this but decided that we shouldn't buy a complete model; instead we should go on Great Hobbies and try to find a kit that we liked. Being stubborn as I am, it just seemed lame to buy a premade boat. Our first thought was to build an old warship, the Bounty, but quickly realized that that was going to be far too time consuming and maybe a little out of our ability. We toned back our initial excitement a little and decided on building a 1/65 scale Bluenose from Billing Boats. The kit was on sale at the time so I pulled the trigger and ordered it.

That was the start of me having no life for the following 8 weeks.

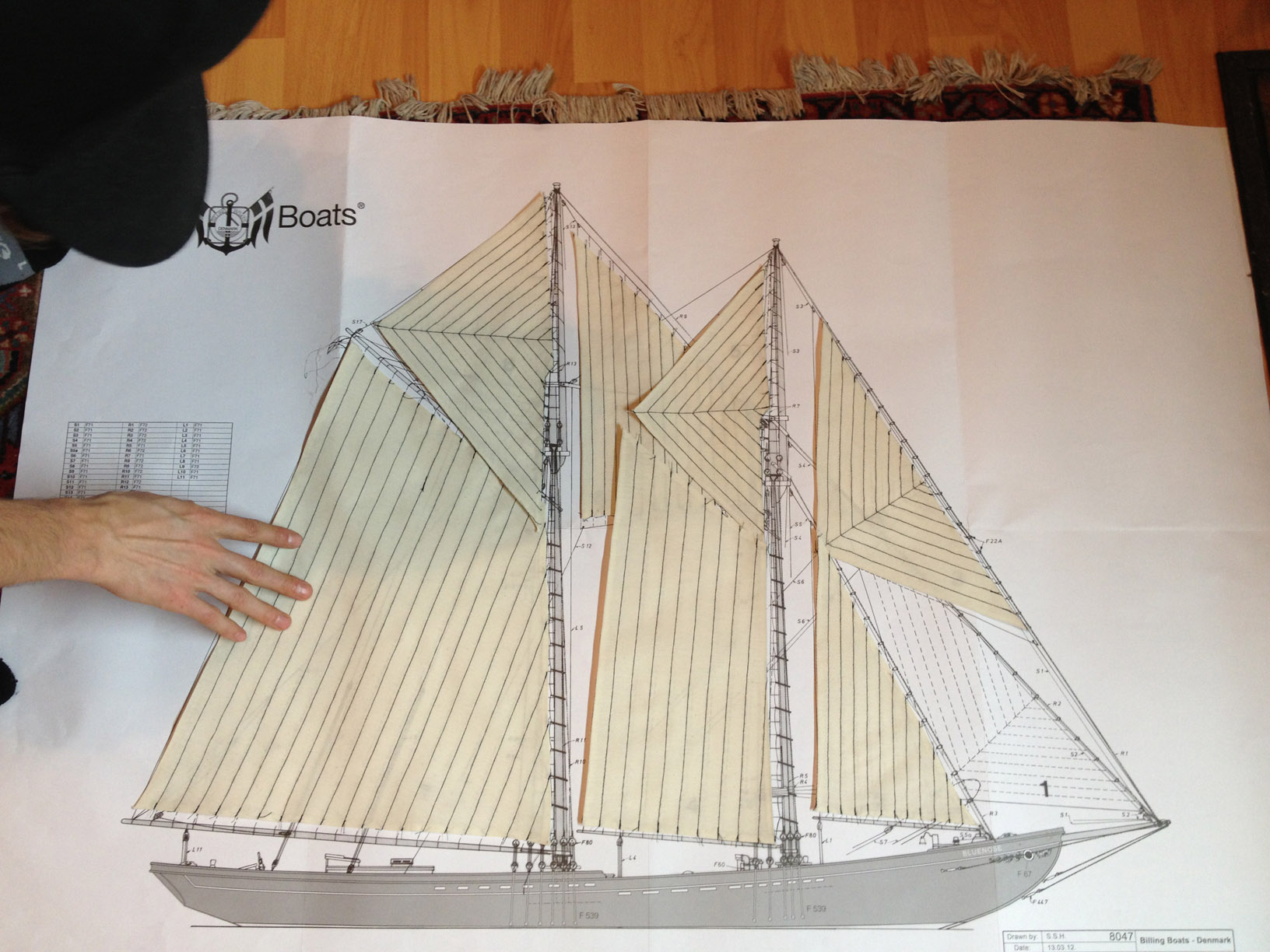

I should probably point out that my knowledge of model ship building or sailing in general is pretty much non existent. I should also point out that Billing Boats has a severe lack of instruction with their kits. By severe, I mean that the instruction book only had 9 steps and none of them were for rigging. With those facts clear before beginning I was still excited to get started and planned on taking six months to complete the boat.

The box arrives at work.

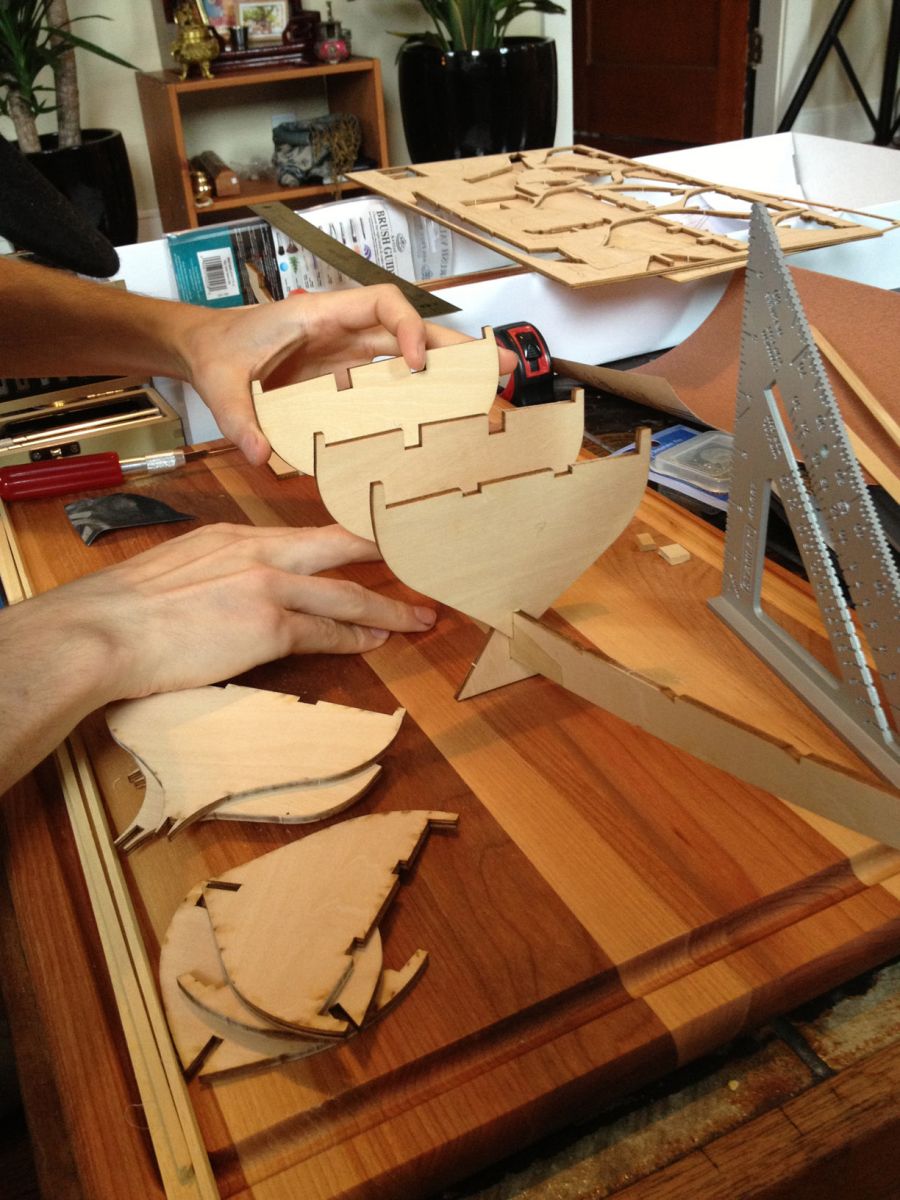

After rooting around through the box trying to figure out what everything was (piles of wood in many sizes, none with any labels) I got started building the keel strip and putting the bulkheads on. It took some time to make sure everything here was totally square. After completing them I clued in that it would have been way smarter to put the deck on while I was installing bulkheads so everything would line up. Miraculously everything lined up anyway.

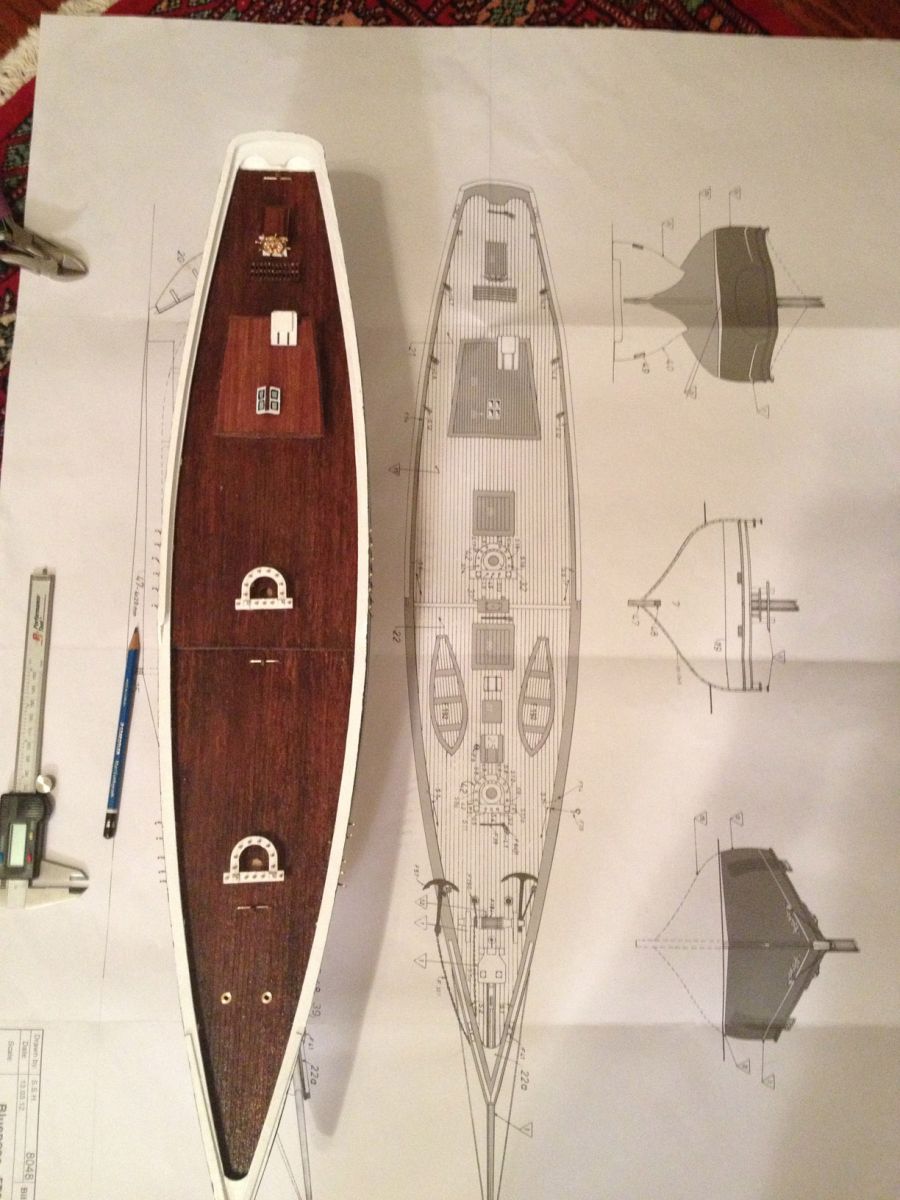

With the 'frame' done it was on to planking. I did the decks before installing them since it seemed way easier to cover them then trim off any excess without them being attached to anything. The decks were pretty straight forward to do and compared to a lot of other parts fairly quick to finish despite the deck planks only being 3mm wide each.

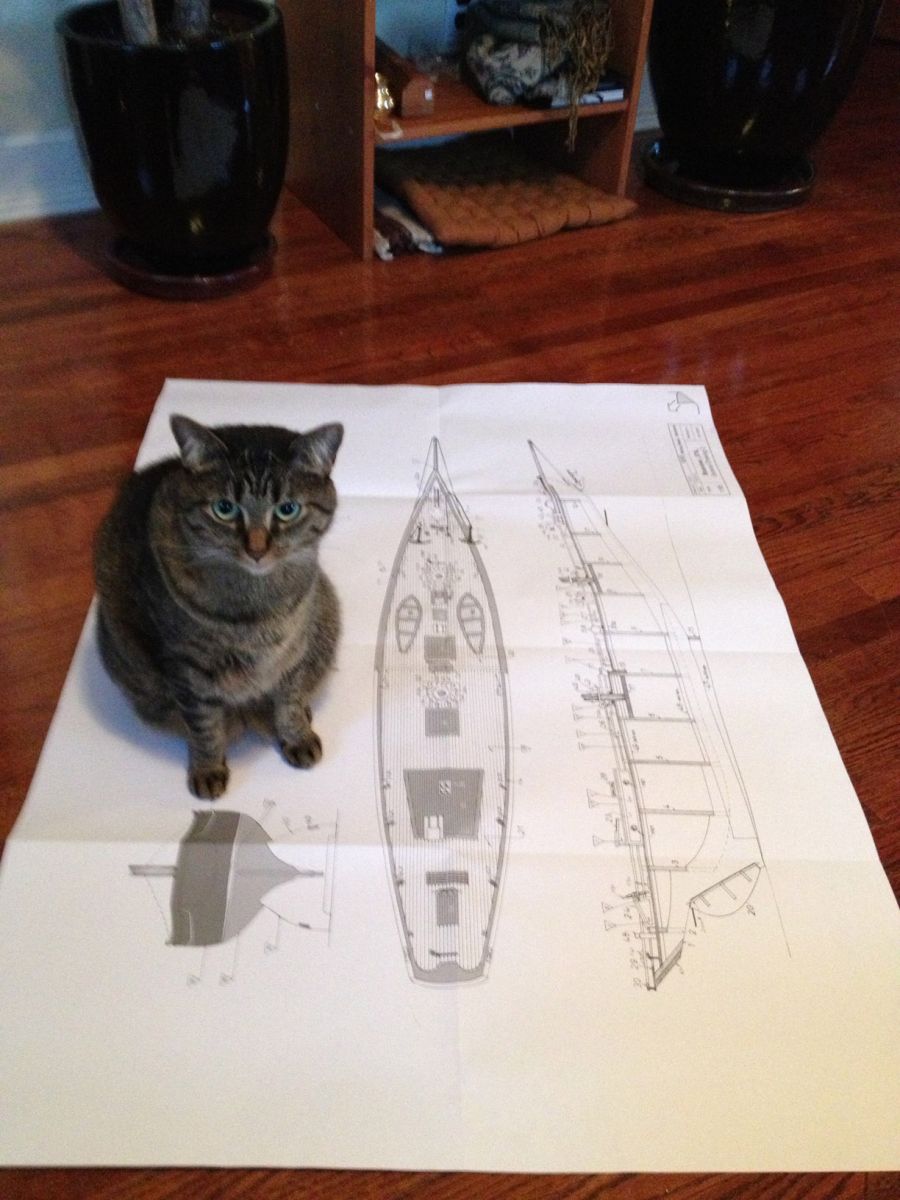

Chali Cat oversaw the progress and enjoys reading blue prints.

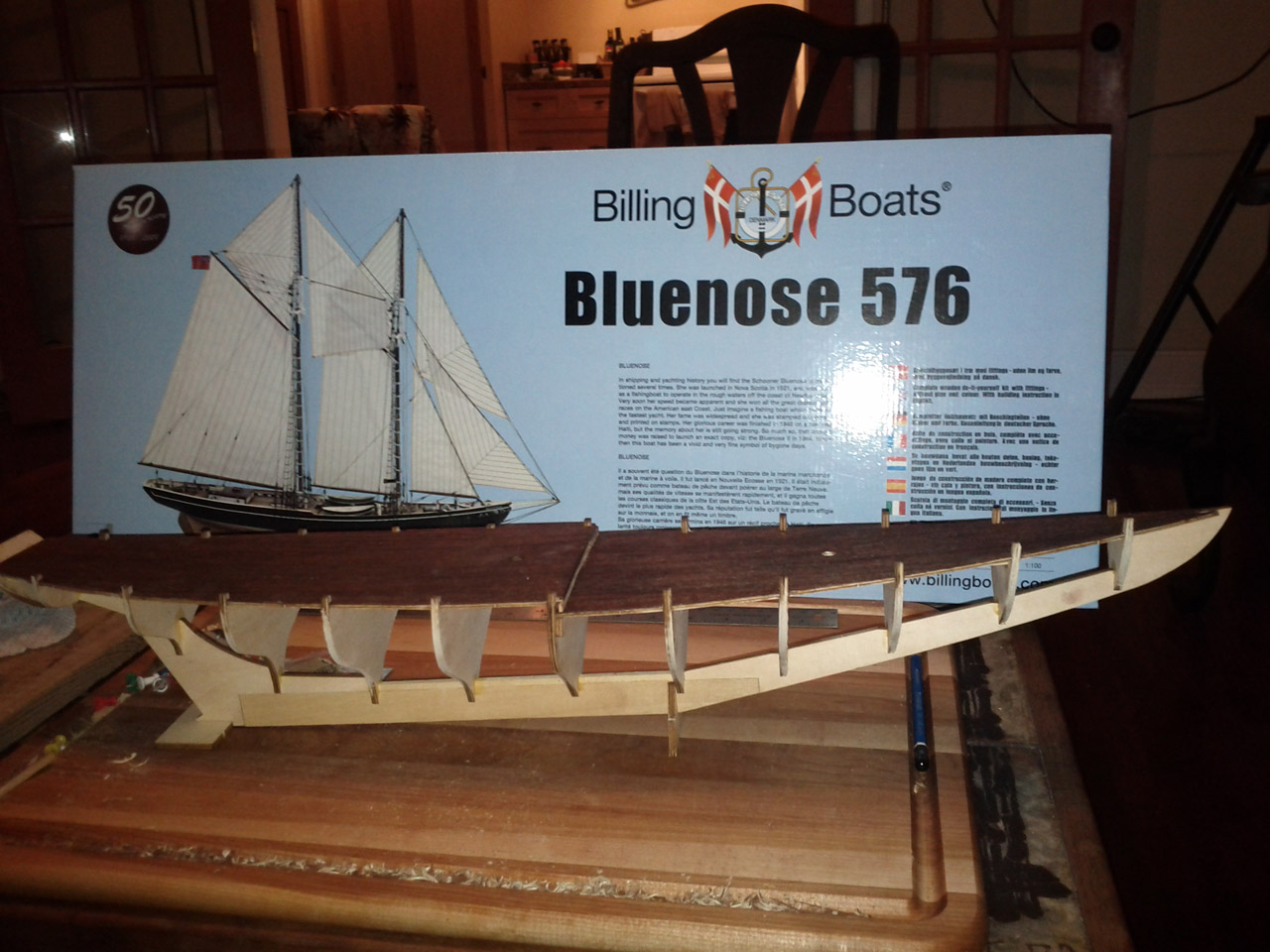

I was a little slow getting into the hull planking because I had no idea how to do it properly. After probably 5 hours of research and reading a 45 page document on planking model ships at least 3 times I said "fuck it" and just went at it. Planking is seriously slow. Almost every board needed to be beveled to fit tightly with the adjacent boards and most of them needed some serious work bending them over a candle to get the right shape. Once the board is glued on you need to pin it down and wait for it to dry before starting another one. You're supposed to alternate one board at a time from starboard to port to make sure that they stay even. By the time I had a pair done the glue was dry enough to start back on the first side again. Quite a bit more internet trolling was done while planking to get an idea of how the stern of the ship was supposed to fit together. The lack of instructions really forces you to assume a lot of things when it comes to tapering, beveling and shaping a lot of the pieces.

I'm pretty sure it took about 20 minutes on average per hull plank so it was pretty sweet when I was finished and got to sand everything. Things fit together pretty tight and I only needed a few tiny dabs of wood filler to smooth things out. Once the handrails were installed it was time to give things a paint job and clear coat the hull.

According to the the microwave I stayed up way too late that night.

One sloppy paint job later and it was time to move on to the deck objects. Kamala stepped in and helped me with some of this stage since it was something we could work on together. Though it took longer than I had expected to get this part done it was one of the easiest. We also started painting the giant pile of fittings while we worked on cabins to make sure they would be done when I needed them. Some time during this stage we also took a trip up to Kamala's parent's house and got her mom to help us sew all of our sails.

The start of the cabins. Lots of little mahogany planks involved

Intermission for sail making

Chali receives a promotion to "Admiral Chali Cat" and continues to observe our progress. We couldn't find a proper sailors hat for her.

Bucket of painted fittings drying.

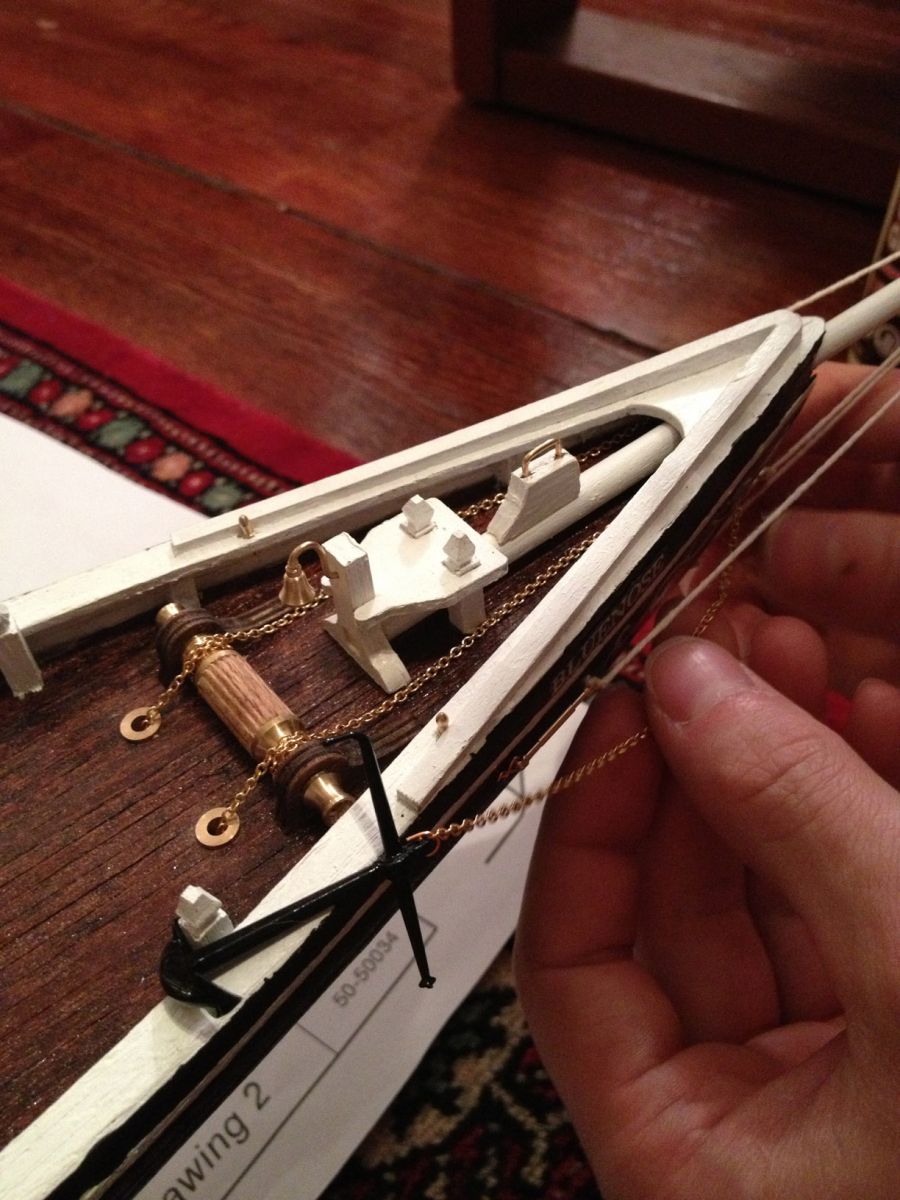

Anchors, bell, and everything else glued to the deck.

Mast building and rigging are the only things left at this point. Building the masts only took a few evenings. I was pretty surprised that tapering all of the masts and booms didn't take longer by hand.

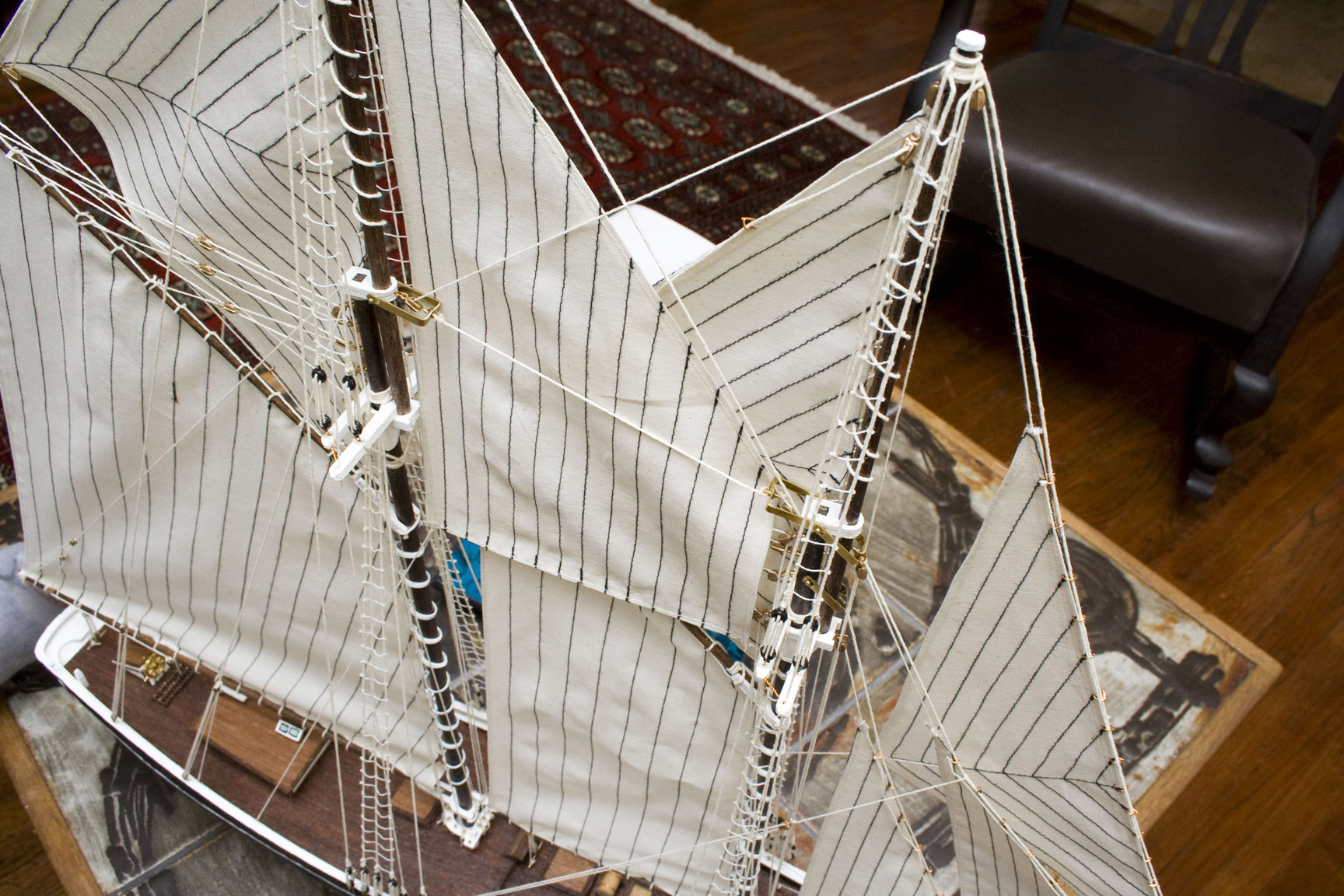

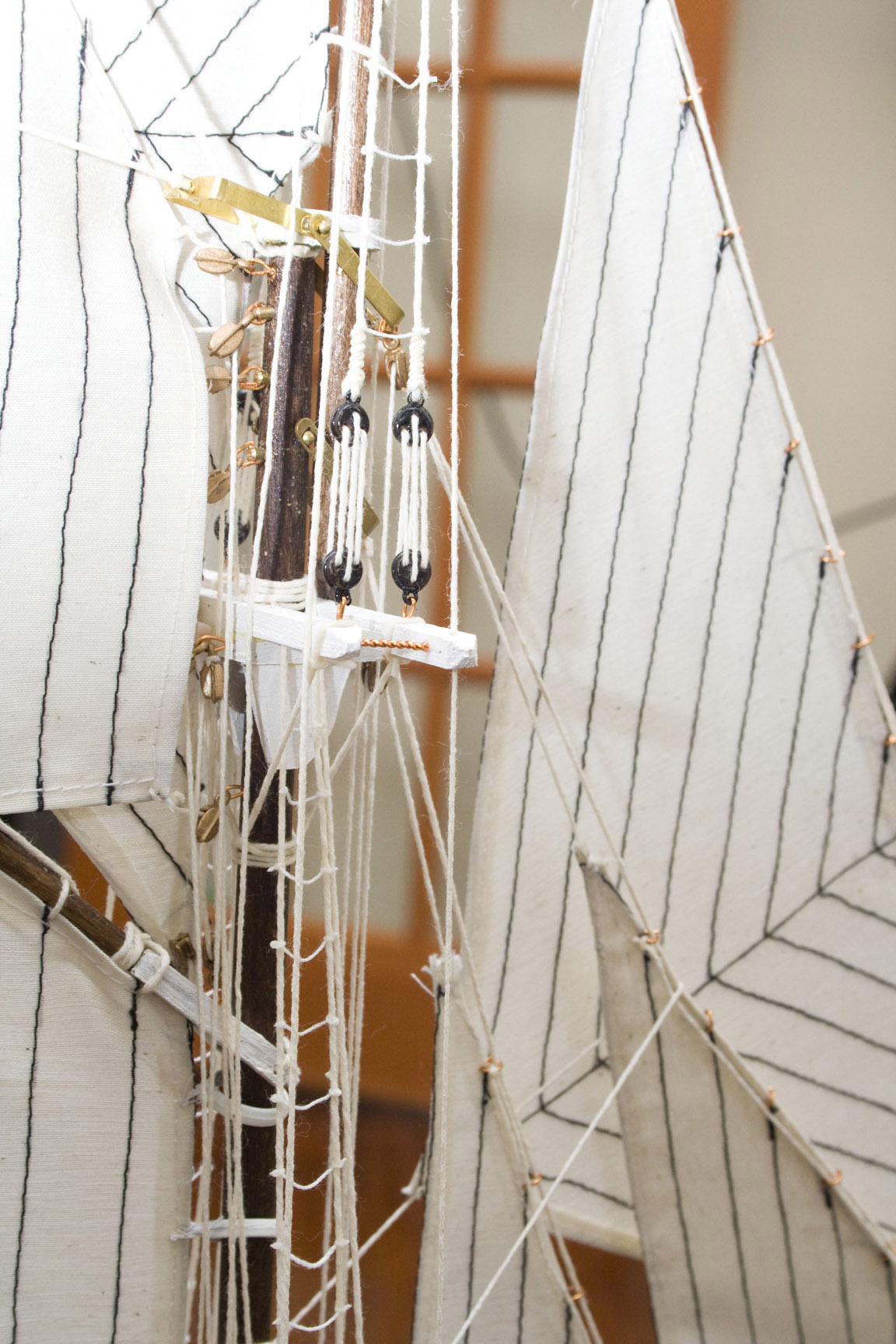

Only rigging left, but that's no small task. The only instruction for any of the rigging was a single view on the blueprint so it took some time to decipher what needed to go where. I'm sure that would have been a lot easier if I had the slightest clue how a large sail boat worked. It was a bit of a puzzle deciding what order to do things in. I decided to only do a few of the shrouds to begin with to get the masts roughly in place. I didn't want to get all of them in so that I would have enough room to get my mitts in place to put in the running rigging.

Once all of the rigging was in place and tensioned I did the ratlines and the the last couple of shrouds. I left that stuff until last so that it wouldn't be in my way getting to all of the belay pins to tie off the running rigging. Ratlines took quite a bit longer than expected at probably 7 hours to get them finished. With the rigging finished all that was left was a few minor details on the deck and two months after starting the Bluenose was finished. I could have spent way longer building this and gotten far more picky with details but it seemed like it was time to move on to other projects and get my life back. The next project is going to be a copper and plexiglass shelf/case with LED lights to display the boat. It will probably be a while before I want to do another large model like this again though.

Check out all of the finished build photos below.

- Log in to post comments

- 124631 reads

Comments

JB - Very cool.

January 07 2013

Blair - Thanks JB

January 07 2013

paul - building the bluenose

September 26 2013

Blair - Thanks for the comment!

September 28 2013

Eric - Rigging

November 11 2013

Blair - Thanks for the comment Eric,

November 12 2013

Carlos - Great ship

March 02 2014

Blair - Nice! Send me a link to

March 03 2014

Carlos - Great ship

March 07 2014

Kent Frandsen - Bluenose

March 07 2014

Carlos - Great ship

March 07 2014

Suavek - Great Job!

April 24 2014

Blair - 400 Pages? That's nuts.

April 24 2014

Stephen - Bluenose

April 28 2014

Blair - More Photos!

April 28 2014

Dennis - About the brass hardware

September 24 2014

Blair - Fittings

September 27 2014

Rinaldo - Bluenose II by Billing Boats

September 27 2014

Blair - glue

September 28 2014

Ron Brown - Thank you thank you thank you!

February 26 2015

George - Beautiful job!

December 30 2015

Blair - Thanks!

January 07 2016

Keith Bell - Bluenose planking

January 05 2016

Blair - Planking

January 07 2016

Mike Carter - Just starting

January 24 2016

Craig - Just starting

February 04 2016

Jason - Sails

March 14 2016

Fredk Brighton - Nearly finished

April 18 2016

Nino Campana - bending wood easily

July 29 2016

norm sunray - Bluenose 1

October 14 2016

Blair - Hey Norm, thanks for the

October 14 2016

norm sunray - Bluenose 1

October 15 2016

Kris - Question and congrats

June 16 2017

Henry - Planking Question

August 31 2017

Blair - Hey Henry, sorry to take a

September 08 2017

Mr Edward W Cresswell - Biuenose 11 Rigging

March 02 2018